ABC Analysis Explained

ABC analysis is one of the most commonly used inventory management methods.

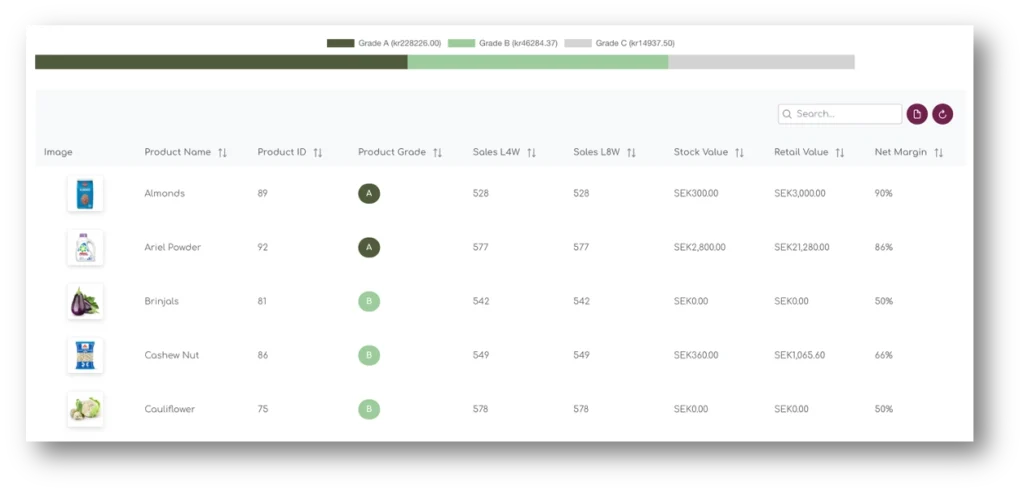

ABC analysis groups items into three categories (A, B, and C) based on their level of value within a business.

Classifying inventory with ABC analysis helps businesses prioritize their inventory, optimize operations, and make clear decisions. Coming up, we’ll explore ABC analysis in-depth, explain how to use it, and help you decide if it’s right for your business.

Table of Contents

Why use ABC analyses for your stock management?

As the name implies, ABC analysis sorts inventory into three main buckets:

A items:

This is your inventory with the highest annual consumption value. It should be your highest priority and rarely, if ever, a stockout.

B items:

Inventory that sells regularly but not nearly as much as A items. Often inventory that costs more to hold than A items.

C items:

This is the rest of your inventory that doesn’t sell much, has the lowest inventory value, and makes up the bulk of your inventory cost.

Inventory categorization is essential with physical products because it protects your profit margins and prevents write-offs and losses for spoiled inventory. It is also the first step in reducing obsolete inventory, supply chain optimization, increasing prices, and forecasting demand.

ABC Analysis and the Pareto Principle

The Pareto principle, also known as the 80/20 rule, states that 80% of outputs are caused by 20% of the inputs.

The principle was discovered by Italian economist Vilfredo Pareto, who observed that 80% of the peas in his garden came from only 20% of the pods he planted. More significantly, he noticed a similar ratio when he realised 80% of land in Italy was owned by 20% of the population.

Since then, the Pareto principle has changed how economics is studied and how we understand the distribution of the world’s resources.

The way Pareto’s Principle factors into ABC analysis is how it is used to prioritise and sort specific inventory over others. ABC analysis brings simplicity to inventory analysis by putting all of your stock into three buckets, enabling you to make more strategic decisions.

ABC inventory analysis is based on the Pareto Principle, meaning it’s often the case that about 20% of a company’s inventory accounts for 80% of its value. This insight enables leaders to make more operationally informed decisions.

Advantages of ABC Analysis

The metric can be used across a lot of different areas of your business, here are some examples:

1. More accurate demand forecasting

Using ABC analysis, inventory planners can predict the demand for specific products and manage their inventory accordingly. This insight minimises carrying costs for obsolete items, thus improving your supply chain management.

Grading your products also assists in assessing whether your supply chain has the right balance of inventory, considering demand variability and safety stock.

2. Better control of high value inventory

The success of many businesses hinges on their A-grade products. ABC analysis enables you to identify those items in real-time, monitor demand for them, and ensure they’re never out of stock.

By channeling your resources towards high-priority inventory, you can rest assured you’re putting the odds of success in your favour.

3. Improved pricing

An ABC analysis can optimise your pricing strategy for products that bring the most value to your business. Once you understand which products are in high demand, you can increase their price, which can significantly impact profits.

How does Shelf Planner help you?

To perform an ABC analysis for your business, Shelf Planner is following the following three steps when providing you with recommendations:

1. Create rules for stock grades

For your different inventory grades (A, B, C), create a set of rules or actions for how your classifications should function. For example, class A inventory should never have a stock out or have a certain turnover threshold. Then for C-class items, it’s fine if you have stock-outs, but you don’t want to write off any spoiled inventory.

You could rely on an inventory management solution to gain rapid insight into how your team performs relative to these standards.

2. Create rules for stock grades

The way you classify your inventory depends on what kind of business you’re running and your company’s objectives. Your classifications should align with the type of inventory you hold and how your business is run.

Any metric you use should measure your inventory’s consumption value for a given period. Standard metrics are total sales, gross margin, purchasing costs, and holding costs. After you calculate the percentages for each item, Shelf Planner will run the analysis on a regular basis and classifies them in your A, B, and C grades.

3. Monitor and present opportunities for change classes

As you grow and add items to your assortment, your classification mix will change.

If you continue to monitor your analyses, you’ll start to notice patterns and be able to forecast which inventory is most vital for you to manage and which are least important. By always having the right inventory mix, your operations will run more efficiently, and cash flow nightmares will eventually be a thing of the past.

Once all stock has been reviewed and categorised, the next step is to implement your ABC analysis. The following section shares some recommended ways to make the most of this approach in your business.

Automated inventory management with Shelf Planner

Shelf Planner’s AI-based inventory management platform supports you with all the tools you need to optimise your business.